Domestic and Imported:

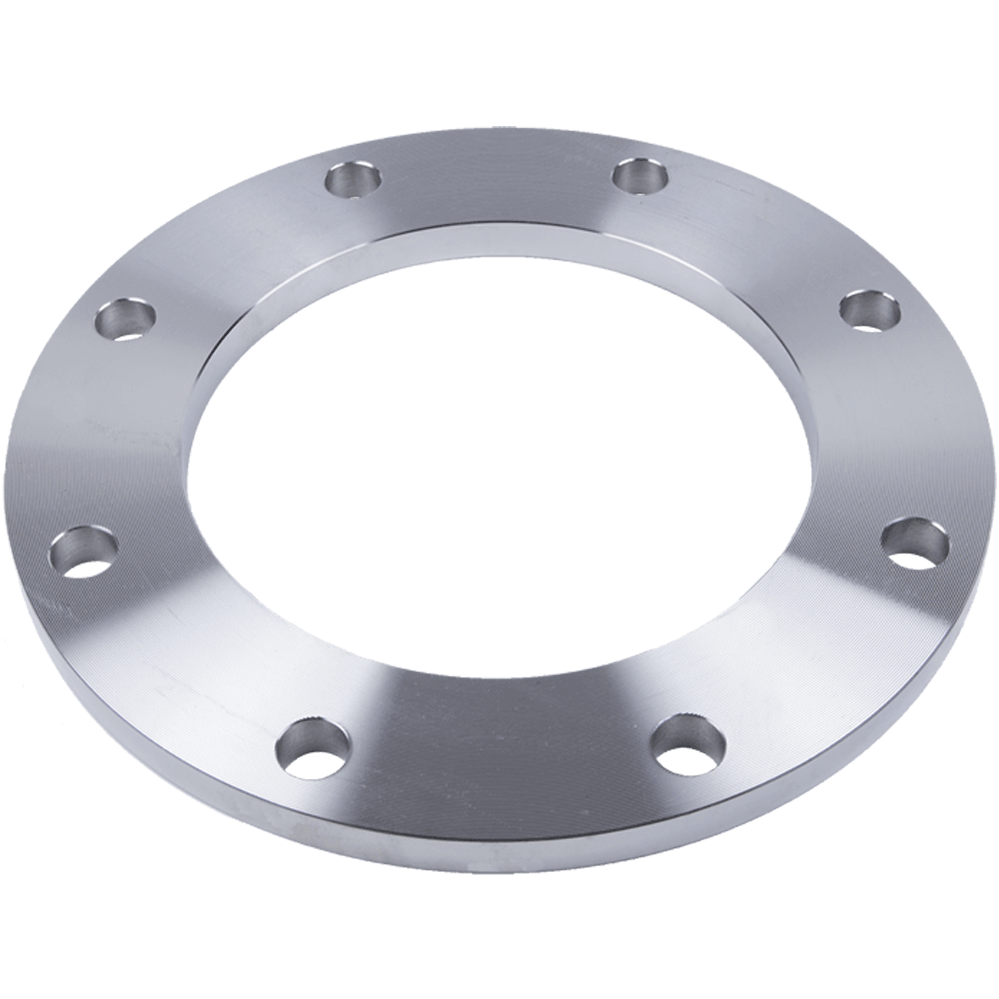

AWWA, ANSI, DIN, Plate, Backing Flanges

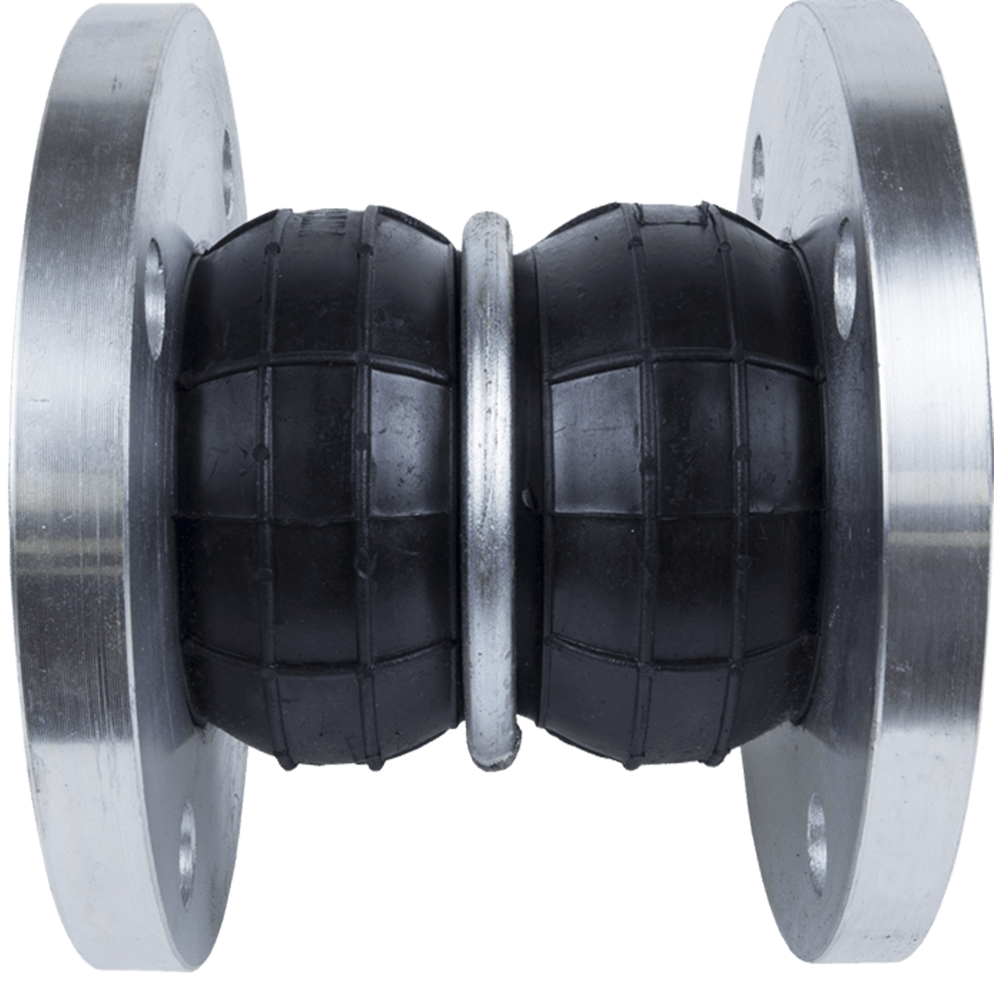

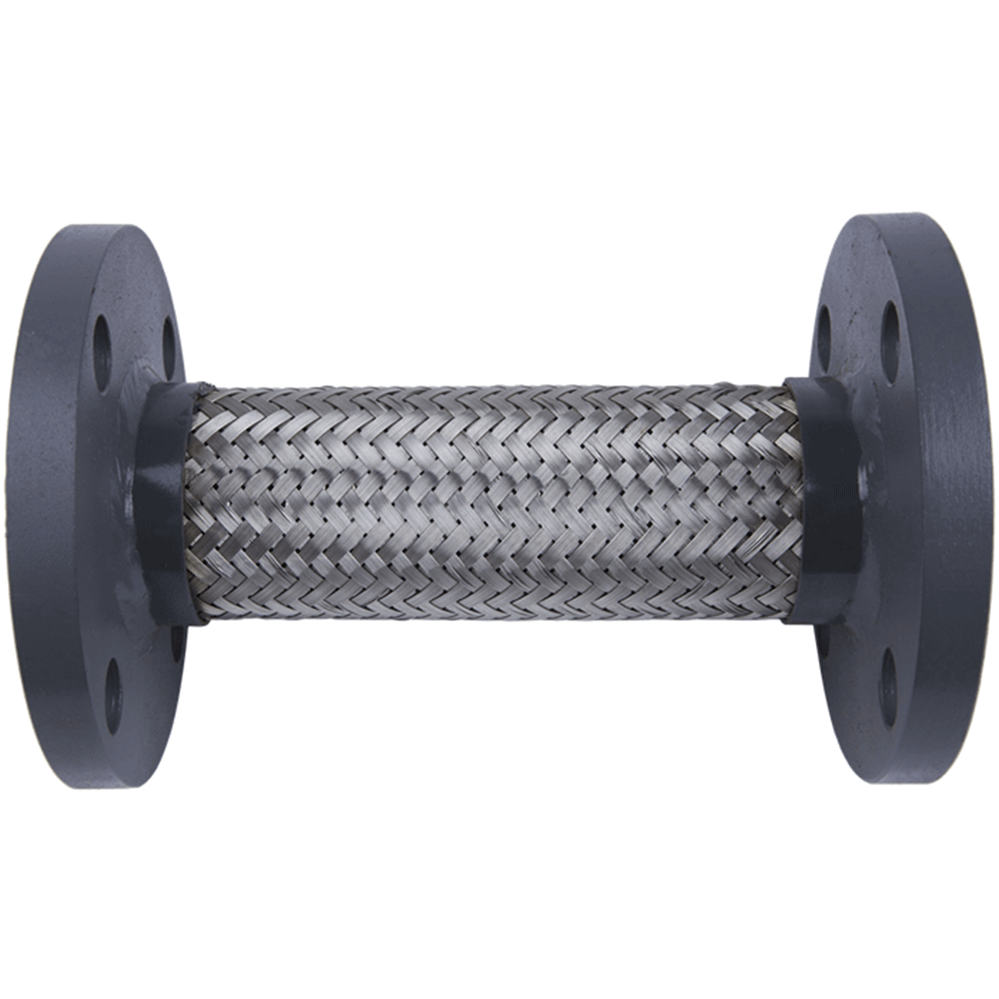

Flanged & Union Rubber Expansion Joints

Flanged & Threaded Pump Connectors

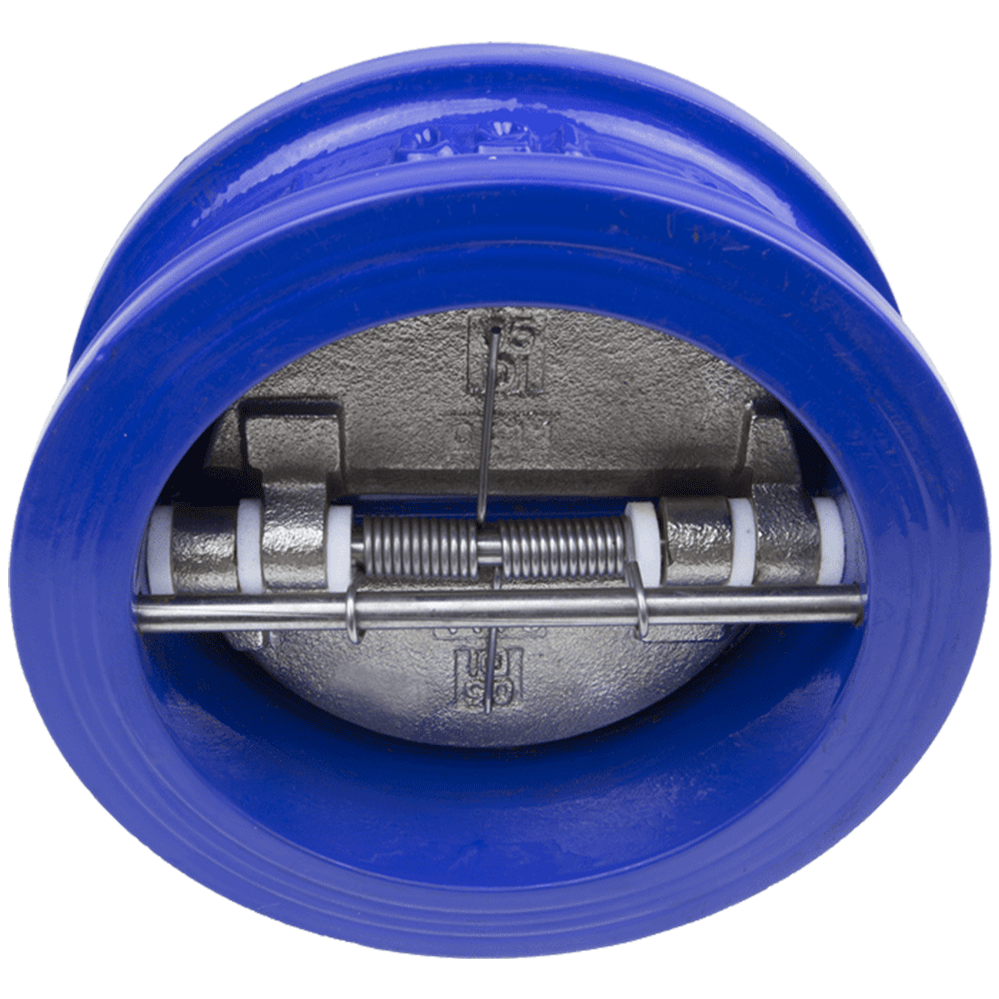

Butterfly, Check & Pressure Relief Valves

Grooved Piping Systems, Other Fittings & Accessories

Custom Parts Manufacturing & Fast Turn Modification

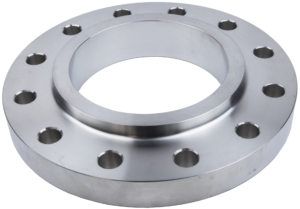

A Weld Neck Flange consists of a circular fitting with a protruding rim around the circumference.

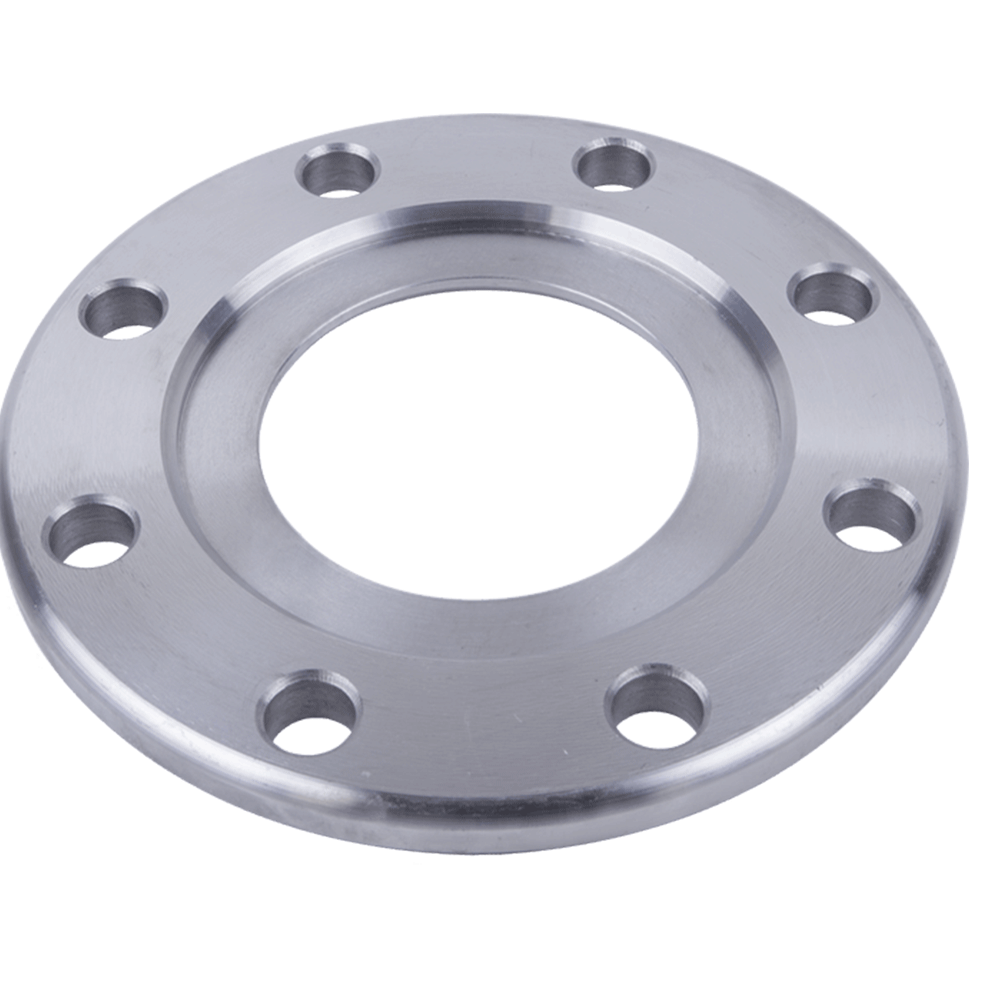

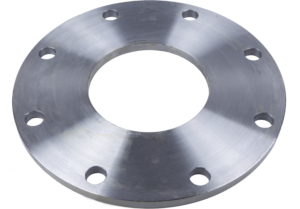

A Slip On Flange is a type of pipe flange that is slipped over the end of a pipe and welded in place.

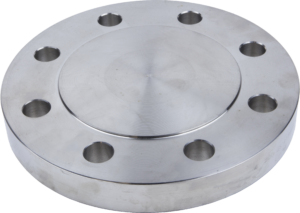

A Blind Flange is a detachable sealing device used to block off a pipeline or to create a stop.

A Socket Weld Flange has an internal stop to support pipes when welding - a great alternative to Weld Neck Flanges

An Orifice Flange is used to measure the flow of product through the piping system.

A Reducing Flange eliminates the need for a separate reducer component because of its smaller diameter bore size.

At API, we are committed to providing exceptional customer service and guaranteeing that our clients receive the right products and services for their specific requirements. If you’re looking for reliable solutions for agriculture, exhaust, HVAC, or water works, we’re here to help you every step of the way. Trust us to be your go-to source for all your industrial supply needs!

Our customer service team is highly responsive and takes full ownership over every order.

Products meet customer requirements and quality control is built in throughout our process.

The right products are in inventory and shipments arrive on time to meet customer need.

Modifications can be made to standard parts, or we can manufacture custom parts, to rapidly respond to customer need.

Who we are

API International is a manufacturer and wholesale distributor of flanges, expansion joints, valves, other pipe fittings and custom fabricated parts. We offer a wide variety of AIS & imported flanges along with other industrial pipe fitting and accessories. Customers turn to us when they need quick delivery of parts and are looking for a higher level of customer service. Standard parts are stocked in one of our conveniently located warehouses for quick distribution throughout the United States.

Customer Reviews

API International, Inc.

12505 SW Herman Road

Tualatin, OR 97062

API International, Inc. | All rights reserved. | Terms & Conditions | Privacy Policy