API International is a manufacturer of flanges, expansion joints, valve accessories, other pipe fittings, and custom-fabricated parts. We offer a wide variety of AIS imported flanges along with other industrial pipe fittings and accessories. Customers turn to us when project deadlines are tight, parts are hard to find, and they need fast shipping plus expert support to keep their operations on track.

We begin by understanding your goals, whether it's reducing cost, improving quality, or launching a new product. Together, we define technical and commercial requirements to ensure full alignment from the start.

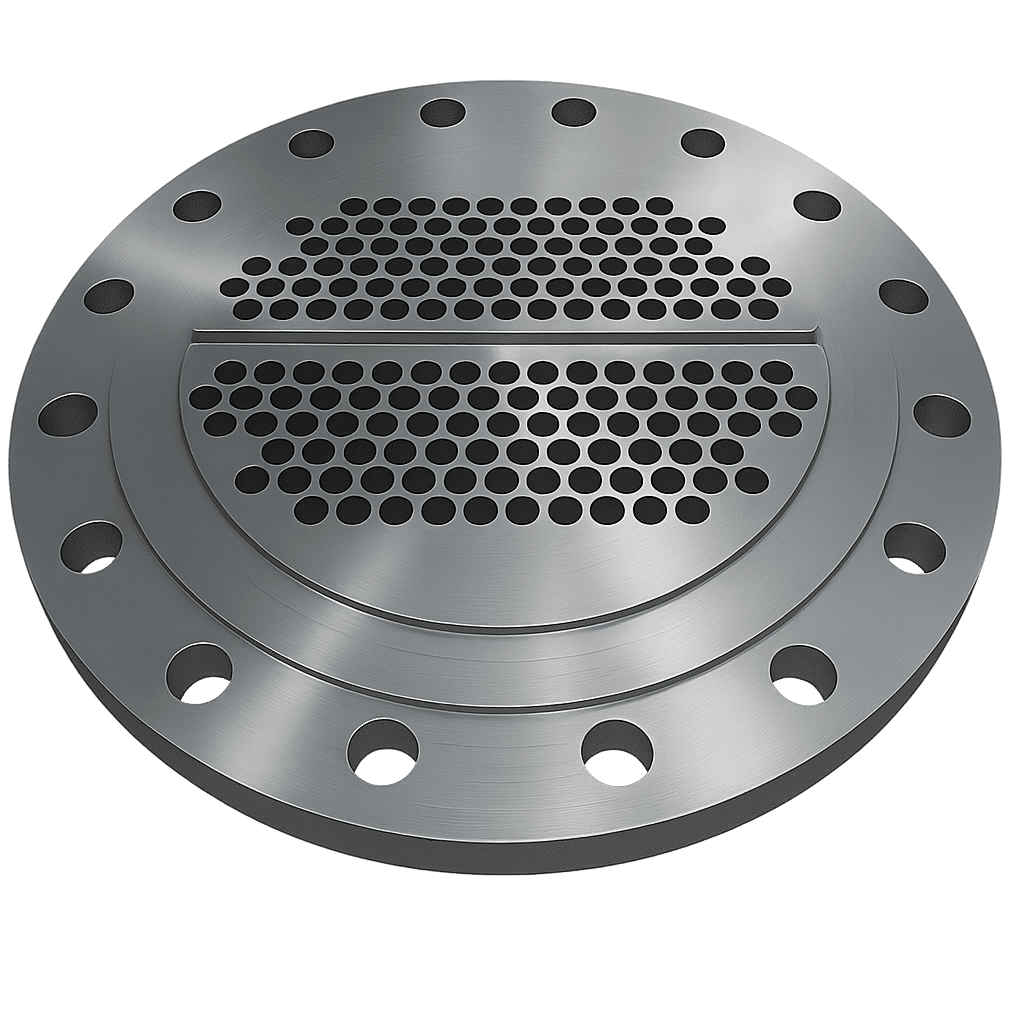

With worldwide manufacturing resources, API International provides both standard and custom flange solutions. Our network of facilities and in-house expertise allow us to deliver the right fit for your needs, whether it’s off-the-shelf or built to specification.

Our engineers work closely with customers to refine designs, reduce costs, and ensure manufacturability. We stay connected with your team throughout to keep progress clear and efficient.

After final review of samples, production begins. Our team oversees quality and delivery coordination to ensure smooth execution and traceability from start to finish.

“API is both very timely and responsive to customers while providing excellent customer service, great quality products, and fostering and maintaining excellent relationships with their customers.”

“Fantastic customer service! API is a great company to work with, their employees are great, and their products are as well!”

“API does a really good job of helping our company and we appreciate the partnership. API has the ability to work with us on special project pricing and lead times.”

“We have been purchasing flanges & fittings from API for over 25 years. Excellent customer service from management to sales staff and timely delivery has helped us to keep our customers happy.”

“API is very quick with quotes and getting back to us on PO status. I have no complaints on my end.”

“Our service experience and company relationship with API has been great. API provides an excellent service experience for their customers.”

“API has been a go to flange supplier for over 20 years. Their extremely fast order processing makes placing and receiving orders seamless.”

“Great customer service. Always a pleasure to work the guys at API. Have been doing business with for 20 years.”

“I am happy with the responsiveness and time frame in which quotes are given. I do not have anything negative to say and think they are doing a good job.”

API International provides high-quality components for waterworks, industrial applications, HVAC, and agriculture with a focus on timely delivery, customization, and customer service.

Most in-stock items ship same-day/next-day to meet your deadlines. Custom orders may vary depending on complexity, but we prioritize on-time delivery.

Yes. Our technical advisors are available to help you choose the right components for your application. Reach out via our contact page or call us directly.

Contact our customer service team with your order number and issue details. We’ll work quickly to resolve the matter and ensure your satisfaction.

Simply complete our New Customer/Credit Application form, available by request. Once approved, you’ll be able to receive orders from API International.

All sales are subject to API International’s standard warranty and terms which can be found here: Terms and Conditions

Yes. Contact your Account Manager for training materials.

We combine deep technical knowledge, high levels of inventory, fast delivery, and a commitment to customization and service. Our team takes ownership of every order to ensure satisfaction.

Absolutely. Our engineering and product teams collaborate with customers to design and deliver custom components that meet exact specifications.

Call or email us info@apiint.com / 503.692.3800 with your needs. Our team will be more than happy to guide you through the technical process and work with your engineers.

At API International, our custom manufacturing capabilities set us apart. With an in-house machine shop, we transform your designs into precision parts quickly. From single prototypes to full production runs, we deliver cost‑effective pricing, dependable performance, and rapid turnaround. Flexible material options and rigorous quality checks ensure consistency from part to part.

99.5% order accuracy rate

Our boots-on-the-ground approach ensures close collaboration with our suppliers. Every flange, valve, and fitting undergoes rigorous inspection and thorough documentation, ensuring consistent performance and reduced field issues.

Active customers in all 50 states + Canada and Mexico

When your schedule is on the line, knowing our U.S. warehouses are stocked and orders ship same-day gives you peace of mind, so you can focus on the task at hand, not the clock.

700+ machined-to-spec parts created each year

Collaborate directly with our engineers to bring your unique specifications to life, ensuring every component performs as if it were built with your project in mind.

1,500+ unique customers served over 45+ years

Our dedicated account team partners with you from quote to delivery, answering questions and offering expert advice so you can make confident decisions and avoid costly delays.

At API International, our commitment to engineered precision, collaborative problem-solving, and rigorous quality assurance helps reduce your total cost of ownership. We streamline manufacturing workflows, eliminate errors, minimize design revisions, and ensure product dependability, delivering integrated solutions that save you time, money, and operational stress.

Pipe flanges are made to be able to withstand extreme conditions and provide long-term service. Yet in practice, these parts remain one of the most vulnerable pieces in piping systems. Failures often happen at the flange joint because of their

Flanges are taking an important part in many piping systems, they provide a secure way to join pipes, valves, pumps, and other equipment. Flanges are widely used in industries like oil and gas, waterworks, chemical processing, and power generation because

Flanges you select for your piping system must match the pipe material, size, pressure class, facing type, and service conditions to ensure mechanical integrity and standard compatibility. Most metallic pipe systems in the U.S. reference ASME B16.5 (NPS ½–24) and

The material selected for a flange encompasses several key factors, including performance, reliability, and longevity. The choice of flange material must suit the operating conditions, which include temperature, pressure, fluid chemistry, mechanical loading, and environmental exposure. In this article, we

Flanges are fundamental components in piping, pressure vessels, and countless mechanical systems. They join pipes, valves, pumps, and equipment into safe, reliable, and functional systems. Flanges are typically attached by welding, threading, or lapping, and are considered the second most

A pipe flange is a standardized, round or square rim-type element commonly used to connect pipes, valves, or equipment with bolts and a gasket. This type of connection allows for easy assembly and maintenance of piping systems. In this blog,

1. The Role of AWWA Standards When engineers and utilities design water systems, every pipe, fitting, and connection must meet various standards to ensure safety, compatibility, and long-term reliability. In the United States, this type of guidance comes from the

In the design and installation of AWWA flanges, pressure rating is an important factor, but equal attention must be given to the bolt pattern. The way a flange is drilled determines not only how it is fastened but also whether

Pressure rating is one of the most critical specifications of AWWA flanges for a waterworks or industrial pipeline system. A flange’s pressure class determines its ability to safely withstand internal system pressures over time without failure. The American Water Works

Two of the most referenced standards in the flange industry are AWWA C207 and AWWA C228. While they can look similar at first glance, they are engineered for very different environments and material performance. AWWA C207 flanges are typically used